Urethane Molding Services: Flexible Solutions for Your Prototyping and Production Needs

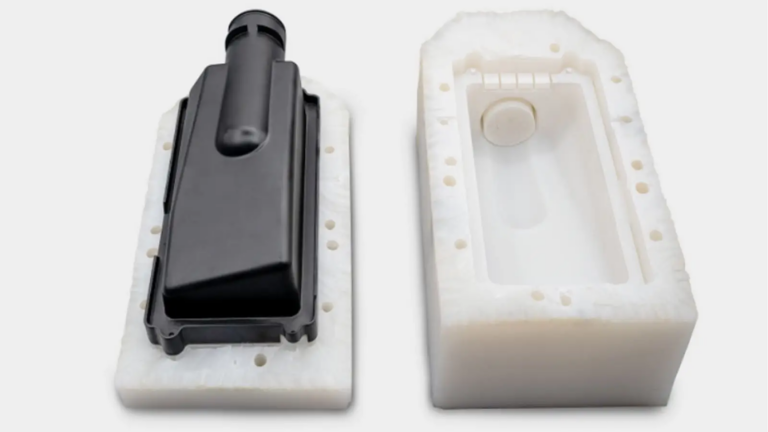

Urethane molding, also known as polyurethane casting or vacuum casting, is a cost-effective method for producing high-quality, elastomeric parts and prototypes. This process is ideal for short to medium production runs and is especially beneficial for creating parts with complex geometries and customized properties.

Urethane materials come in a range of hardness and can mimic properties of materials from rubber to rigid plastics.

Cost Efficiency

Less expensive tooling compared to injection molding, making it ideal for small to medium production volumes.

Versatility in Production

Perfect for a variety of industries, including automotive, medical, and consumer products, where durable and flexible parts are required.

Speed to Market

Quicker turnaround times for production when compared to traditional plastic manufacturing methods.

Types of Urethane Molding Processes

- Open Cast Molding: Suitable for products that do not require tight tolerances or intricate details, typically used for producing large, less complex items.

- Closed Mold Casting: Provides excellent control over part dimensions and is used for products requiring higher precision and finish.

- Vacuum Casting: Used for parts that need superior quality and finish without the expense of hard tooling, often used for prototypes and small batches.

Best Use Cases to Use Urethane Casting

Urethane molding is particularly advantageous for:

- Prototyping of Rubber-like or Plastic Parts: Allows for rapid iteration of design without expensive tooling costs.

- End-Use Parts: Produces high-quality parts suitable for final use in products, especially where fewer than 10,000 parts are needed.

- Market Testing: Create actual user experience samples for market testing before committing to high-volume manufacturing processes.

Urethane Casting or Injection Molding?

Urethane Casting:

- Cost-Effective for Low Volumes: Ideal for small production runs due to lower upfront costs for silicone molds.

- Quick Setup: Shorter lead times thanks to faster mold preparation.

- Flexible Designs: Suitable for complex shapes and intricate details without the constraints of hard tooling.

Injection Molding:

- High-Volume Efficiency: More economical for large quantities as unit costs decrease significantly.

- Strong and Durable: Produces dense, robust parts ideal for functional components requiring structural integrity.

- Material Versatility: Supports a broader range of materials and provides consistent quality across high production volumes.

Decision Factors: Choose urethane casting for early prototypes and low-volume runs where detail and speed are priorities. Opt for injection molding when scaling to high-volume production where durability and cost efficiency are paramount.

FAQs about Our Urethane Molding Services

What is the typical lifespan of a urethane mold?

The lifespan of a urethane mold depends on the specific material and the complexity of the parts being cast, but typically, a mold can produce anywhere from 20 to 100 parts. For projects requiring higher volumes, we often recommend multiple molds to ensure quality and efficiency throughout the production run.

Can urethane molds reproduce complex details?

Yes, urethane molds are excellent for reproducing complex details. The flexibility of the silicone molds used in urethane casting allows for high precision and excellent surface detail, making it suitable for intricate designs and textures.

What is the range of sizes that can be molded?

We can mold parts ranging from small components just a few millimeters in size to large items up to several meters in length. Our facility is equipped to handle diverse size requirements, ensuring versatility and adaptability for various project needs.

How do you ensure color consistency in urethane parts?

Color consistency is achieved through precise measurements and mixing of dyes in the urethane resin. We standardize our color formulations and conduct thorough testing before production to ensure that each batch meets the specified color requirements. Additionally, we maintain strict quality control during the casting process to avoid variations.

What are the finishing options available for urethane molded parts?

We offer a variety of finishing options for urethane parts, including painting, texturing, and polishing to achieve desired aesthetics or functional properties. Secondary processes such as machining or drilling can also be applied for further customization. These finishes enhance the appearance and durability of the final product, tailored to specific client needs.

Get a Free Project Quote

Tell us a bit about your needs and a knowledgeable product specialist will be in touch to gather any additional info and provide you with a secure file upload link to share your project files so we can get you an accurate quote.