Sheet Metal Fabrication Services: Shaping Precision, Delivering Durability

Sheet metal fabrication is a versatile manufacturing process that involves cutting, bending, and assembling metal to create everything from industrial machinery parts to intricate electronic enclosures. Utilizing state-of-the-art equipment and techniques, our services provide high precision and repeatability for projects ranging from simple brackets to complex mechanical housing.

Metal parts offer superior strength and longevity, essential for structural applications.

Cost-Effective for Large Runs:

Economical production method for larger quantities, reducing per-unit costs significantly.

Versatility in Production

Suitable for a variety of applications, from aerospace components to architectural details.

Aesthetic Possibilities

Offers options for various finishes and treatments that enhance appearance and resistance to corrosion.

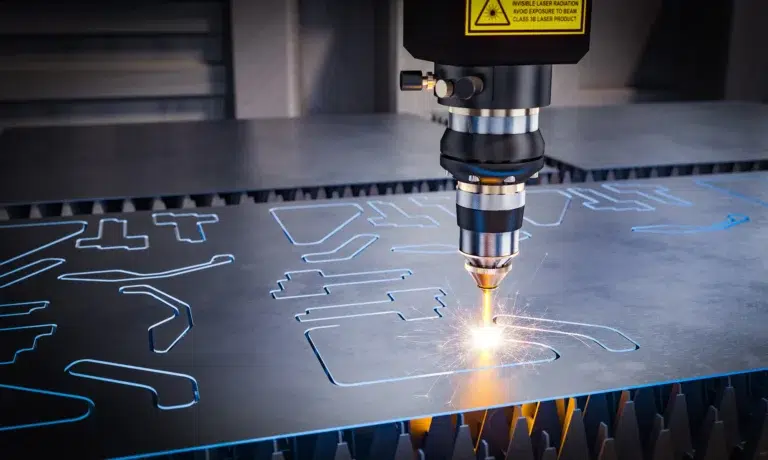

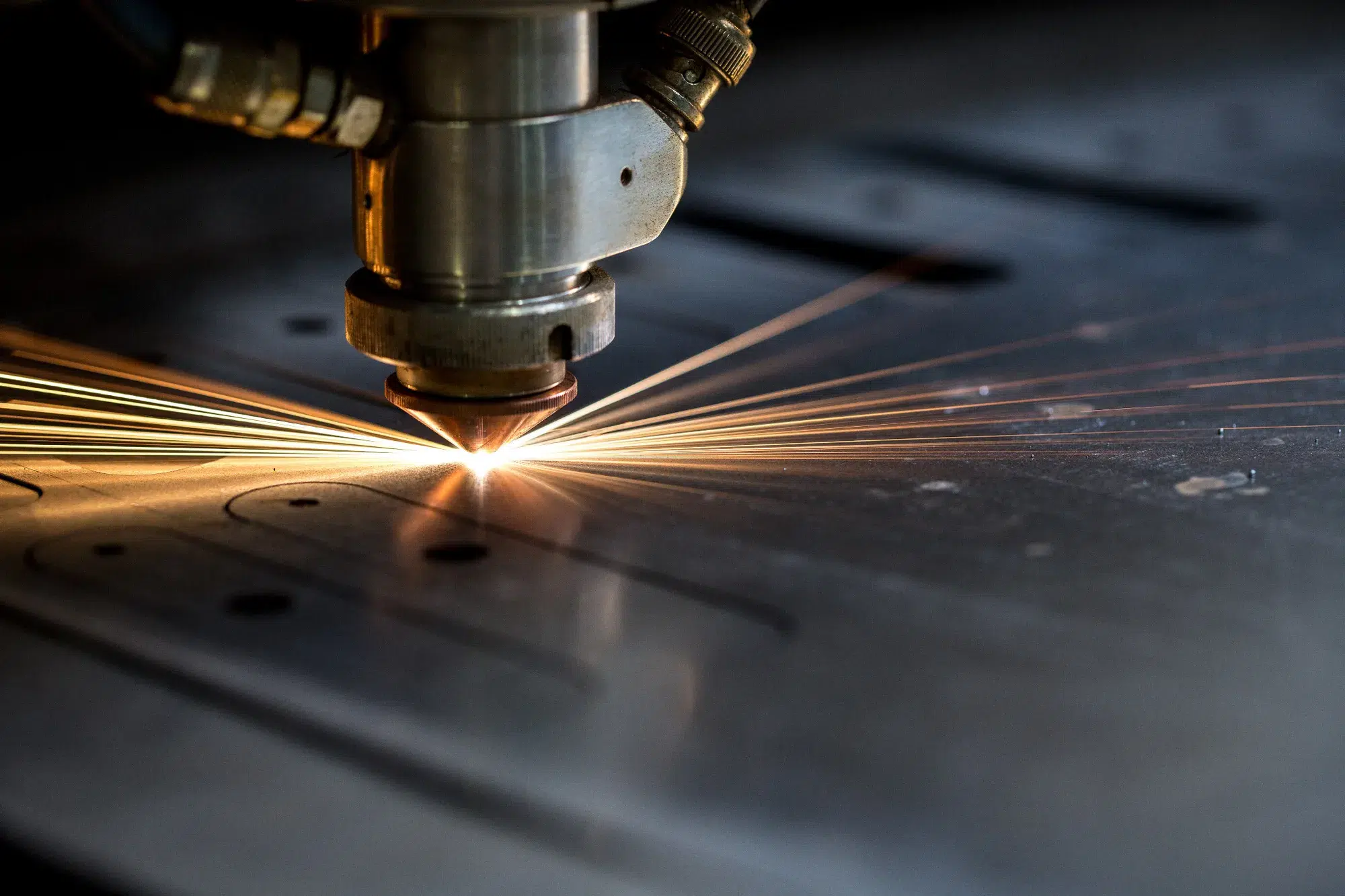

Types of Sheet Metal Fabrication Processes

- Cutting: Utilizes lasers, punches, or waterjets to cut precise shapes from sheets of metal.

- Bending and Forming: Shapes the metal into desired forms using press brakes and other bending machinery.

- Welding: Joins cut pieces into assemblies or complex constructions using techniques like MIG, TIG, or spot welding.

- Finishing: Includes sandblasting, powder coating, and painting to improve the surface quality and durability of metal products.

When to Use Sheet Metal Fabrication

Sheet metal fabrication is particularly beneficial for projects that require:

- High Durability: Components that need to withstand harsh conditions and stress.

- Moderate to High Volume Production: Economies of scale can be achieved for larger production runs.

- Custom Aesthetic Requirements: When the project requires a specific look or finish, such as in consumer products or visible architectural elements.

- Rapid Prototyping to Production Transition: Ideal for prototypes that can be directly translated into production parts with minimal changes.

Materials Commonly Used in Sheet Metal Fabrication

Our fabrication capabilities extend to a wide range of metals to suit various project requirements:

- Aluminum: Lightweight and corrosion-resistant, perfect for automotive and aerospace applications.

- Stainless Steel: Highly durable and ideal for food processing and medical environments due to its ease of sterilization.

- Mild Steel: Cost-effective and strong, making it a staple for general construction and infrastructure.

- Copper: Excellent electrical conductivity properties, often used in electrical components and heat exchangers.

FAQs about Our Sheet Metal Fabrication Services

What thickness of sheet metal can you fabricate?

We can fabricate sheet metal from very thin sheets starting at 0.5 mm up to thicker plates of 20 mm. The range of thicknesses available may vary depending on the metal type, such as aluminum, stainless steel, or mild steel, to ensure optimal processing and quality.

How do you ensure quality in your fabrication processes?

Quality is paramount in our fabrication processes. We adhere to strict ISO 9001 quality management standards, incorporating quality checks at every stage of production—from material selection and processing through to the final inspection. Our facility uses advanced measurement and testing equipment to ensure that all parts meet your specifications and our high-quality standards.

What are the typical lead times for sheet metal fabrication projects?

Can you handle complex assembly requirements?

Yes, our capabilities include handling complex assembly requirements. Our team is skilled in various assembly techniques, from simple mechanical assemblies to more intricate configurations involving welding and joining multiple components. We also offer prototyping services to ensure assemblies meet functional and dimensional requirements before full-scale production.

What finishing options do you offer to enhance or protect fabricated parts?

We offer a range of finishing options to enhance the appearance and durability of fabricated parts. These include powder coating for a durable and visually appealing finish, galvanizing to protect against corrosion, anodizing for aluminum parts to increase corrosion resistance, and various plating options that provide additional surface protection and aesthetic qualities.

Get a Free Project Quote

Tell us a bit about your needs and a knowledgeable product specialist will be in touch to gather any additional info and provide you with a secure file upload link to share your project files so we can get you an accurate quote.