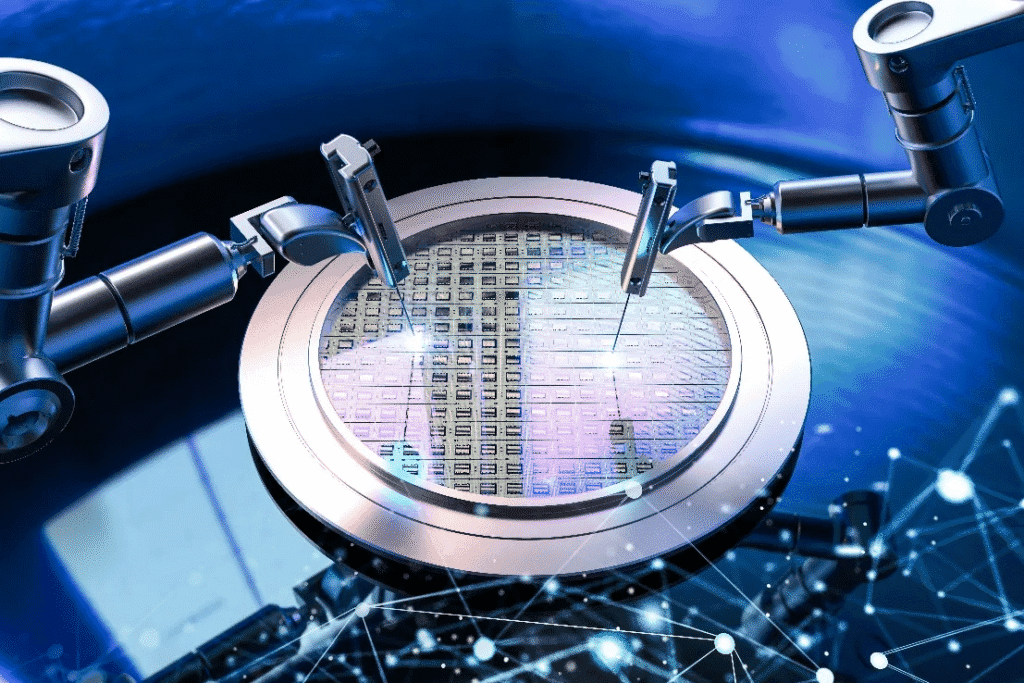

Project Background: Conquering Ultra-Clean and Micron-Level Precision Challenges

In early 2025, as a leading global semiconductor equipment manufacturer was upgrading its wafer handling system, their engineering team encountered persistent quality issues with their high-purity gas control valve bodies. Existing suppliers’ 316L stainless steel components showed microscopic burrs and inconsistent surface finishes, resulting in vacuum seal failures and particle contamination risks—an unacceptable threat in semiconductor manufacturing.

Having learned of our specialized expertise in semiconductor-grade stainless steel precision machining (particularly our vacuum chamber components for etching equipment), their Asia Pacific Procurement Director, James Wong, contacted our Technical Director, Mr. Li. Facing a tight installation deadline for their new production line, they urgently needed 30 ultra-precision valve body assemblies for cleanroom testing, particle analysis, and lifecycle validation.