In May 2025, we received a repeat inquiry from a long-term client based in Ohio, USA—an automation integrator specializing in high-speed packaging lines for the food and personal care sectors.

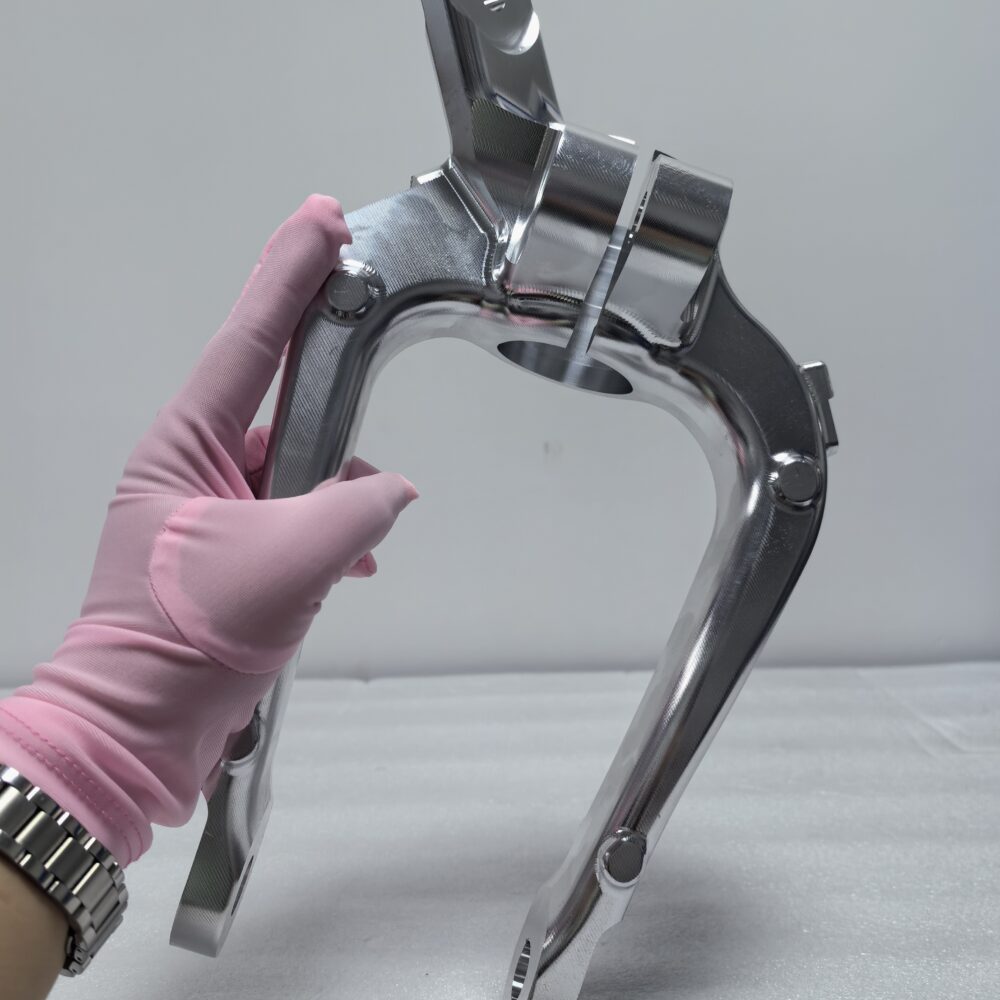

The client was developing a new end-of-line robotic gripper designed for lightweight SKU handling. The design called for a custom-machined aluminum bracket, intended to interface between the gripper’s pneumatic housing and the modular mounting arm. They needed tight tolerances on bore spacing and a clean anodized surface to withstand frequent tool changes.

As a trusted partner familiar with their documentation and packaging expectations, we were brought in to quickly prototype and deliver a pilot batch.