WhatsApp: +86 186-7086-9863

Email: freequote@alecmodel.com

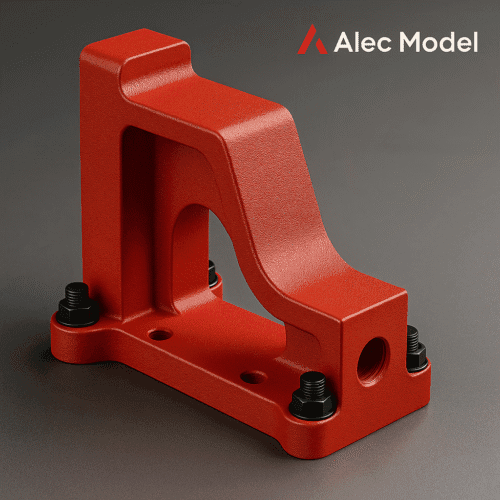

The client provided 3D drawings and technical specifications for three aluminum alloy components, with the following key requirements:

Item | Description |

Product Type | Welded structural steel frames + machined interfaces |

Final Use | Subsea control module platform |

Material | ASTM A36 plate + 4140 alloy inserts |

Tolerance | ±0.02 mm on bore centerlines, ≤0.15 mm flatness across span |

Size (per frame) | 1020 mm × 720 mm × 460 mm |

Quantities | Pilot lot: 3 sets → Batch series: 12 sets / quarter |

Surface Treatment | Blasted + epoxy coated (offshore marine coating) |

Lead Time (Pilot Lot) | 20 working days from drawing approval to dispatch |

Documentation Required | Weld map, WPS/PQR, dimensional inspection, material certs |

Maintaining flatness across wide steel base plates is always challenging due to thermal distortion. The client required maximum deviation under 0.15 mm after welding and machining.

Some interfaces required mounting hydraulic panels with multiple aligned through-holes—spanning from one steel sidewall to another. Hole-to-hole spacing tolerance was ±0.02 mm.

Unlike one-off fabrication, this project demanded consistent part-to-part accuracy across batches. Hole spacing, bolt pattern alignment, and base plate flatness needed to be identical across all units.

The customer previously spent excessive time coordinating schedules and drawings between welders, heat treaters, machine shops, and coaters. They needed a single partner who could own and execute the whole process.

All steel plates were cut and pre-machined in-house from ASTM A36 using CNC plasma and mill.

Welded frames were fabricated by ASME-certified welders using proprietary jigs to control deformation.

After welding, each unit was stress-relieved at 620°C in our local heat treatment facility.

Final precision machining was done in our double-column CNC center using Renishaw probing to set datums and align bores.

Critical dimensions—bolt hole positions, slot widths, bearing surfaces—were all CNC milled within target tolerances.

We created dedicated inspection jigs and datum fixtures to ensure identical setup conditions for each frame.

Inspection data was recorded and reviewed per unit for SPC (statistical process control) purposes.

Lessons from the first lot were locked into CAM and fixture setup, eliminating variance in the next production cycles.

The client noted that our one-source model saved them 3–4 days of handling and transport per unit, and simplified their quality management workload.

This project transitioned into a recurring monthly order, with batch deliveries every two weeks. We’ve also helped the client set up batch traceability templates and inspection routines compatible with their CE and ISO9001 requirements.

Future projects include development of similar modules for a new inverter control platform. Learn more about our 5-axis CNC machining capabilities and how they support advanced copper heat sink machining.

Holding tight machining tolerances after welding

Reliable delivery coordination and documentation

Consistent part-to-part accuracy across batches

Fast response time and organized technical communication

Professional document structure that meets their ISO9001 supplier requirements

Our ability to execute reliable and repeatable copper heat sink machining operations played a central role in this project.

This project demonstrates our strength in high-conductivity copper machining, heat sink structure control, and precision 5-axis workholding. While the core machining process was technically not highly complex, it required meticulous control over burrs, surface finish, and repeatable dimensional tolerances.

More importantly, it reflects our ability to understand the client’s real-world use cases and support them with full-cycle execution—from drawing to delivery.

We’re more than a machine shop. We offer expertise in copper heat sink machining, allowing customers to move from prototype to production with full confidence. We’re a problem-solving manufacturing partner.

WhatsApp: +86 186-7086-9863

Email: freequote@alecmodel.com

601, Rong Qing Building 1, Yangxia 2nd Rd.

Xinqiao St., Baoan Dist., Shenzhen

Guangdong, China 518125

Floor 101, Building 2, No.46,

Huangpu Rd., Baoan District, Shenzhen City

Guangdong China 518125