In Q3 2024, we were approached by a rail technology manufacturer based in France—one of the primary suppliers to SNCF (the French National Railway Company). The client specializes in structural systems and auxiliary power modules for high-speed and intercity trains.

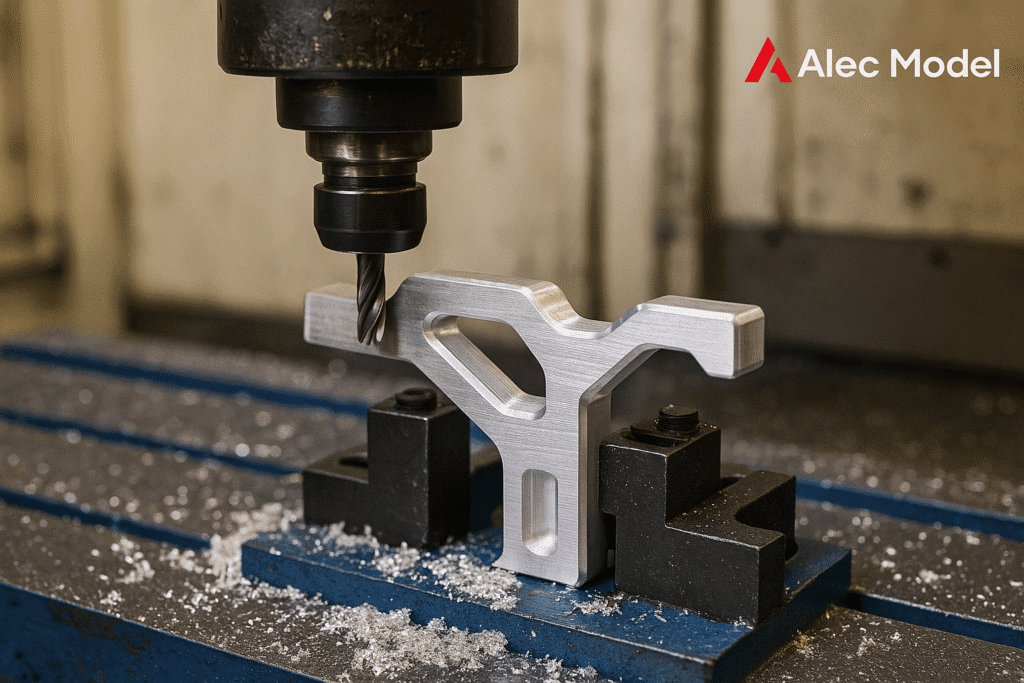

They were developing a next-generation modular power unit, and required custom-machined aluminum brackets and thermal support frames using non-standard aerospace-grade material. The initial goal was to deliver fully machined prototypes for form-fit testing—within 10 working days—along with complete EU-compliant documentation for internal qualification and customs clearance.

WhatsApp: +86 186-7086-9863

Email: freequote@alecmodel.com