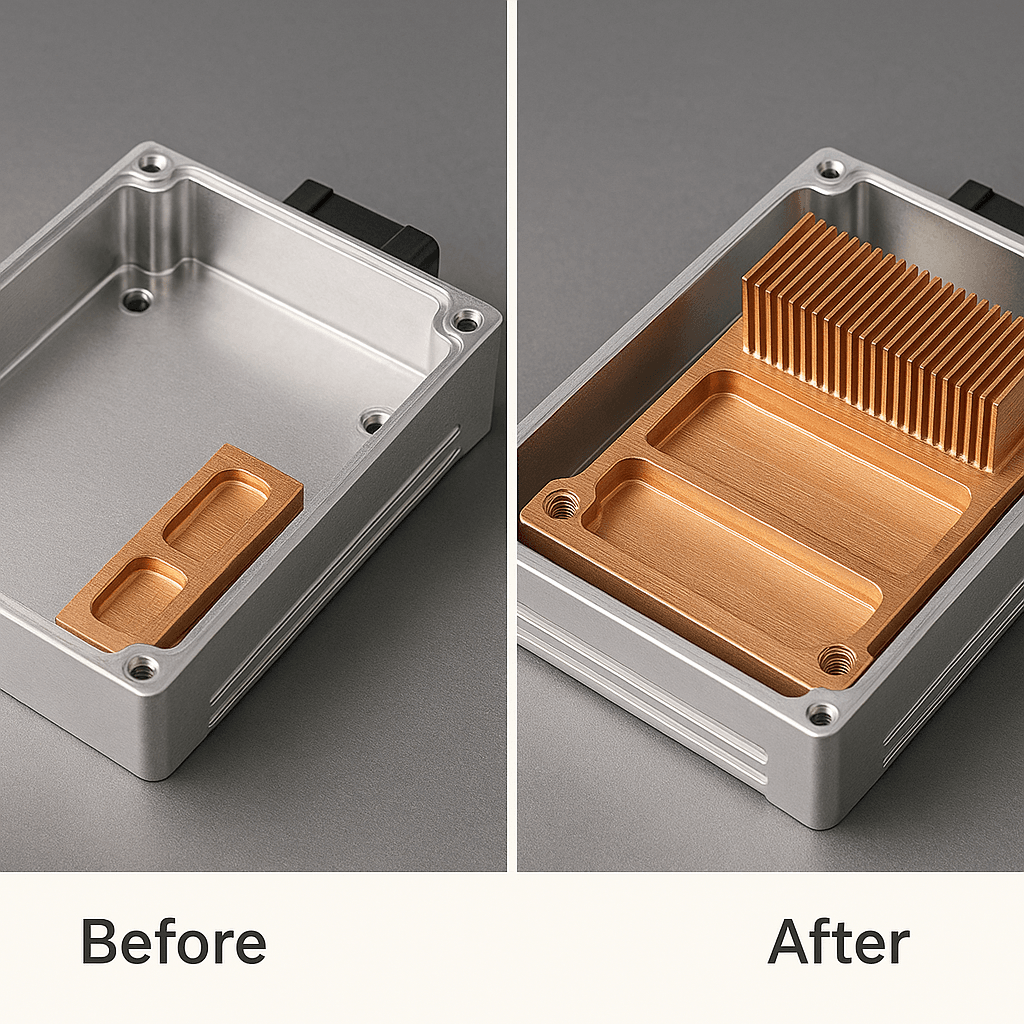

Thermal Component Prototype for Power Electronics:

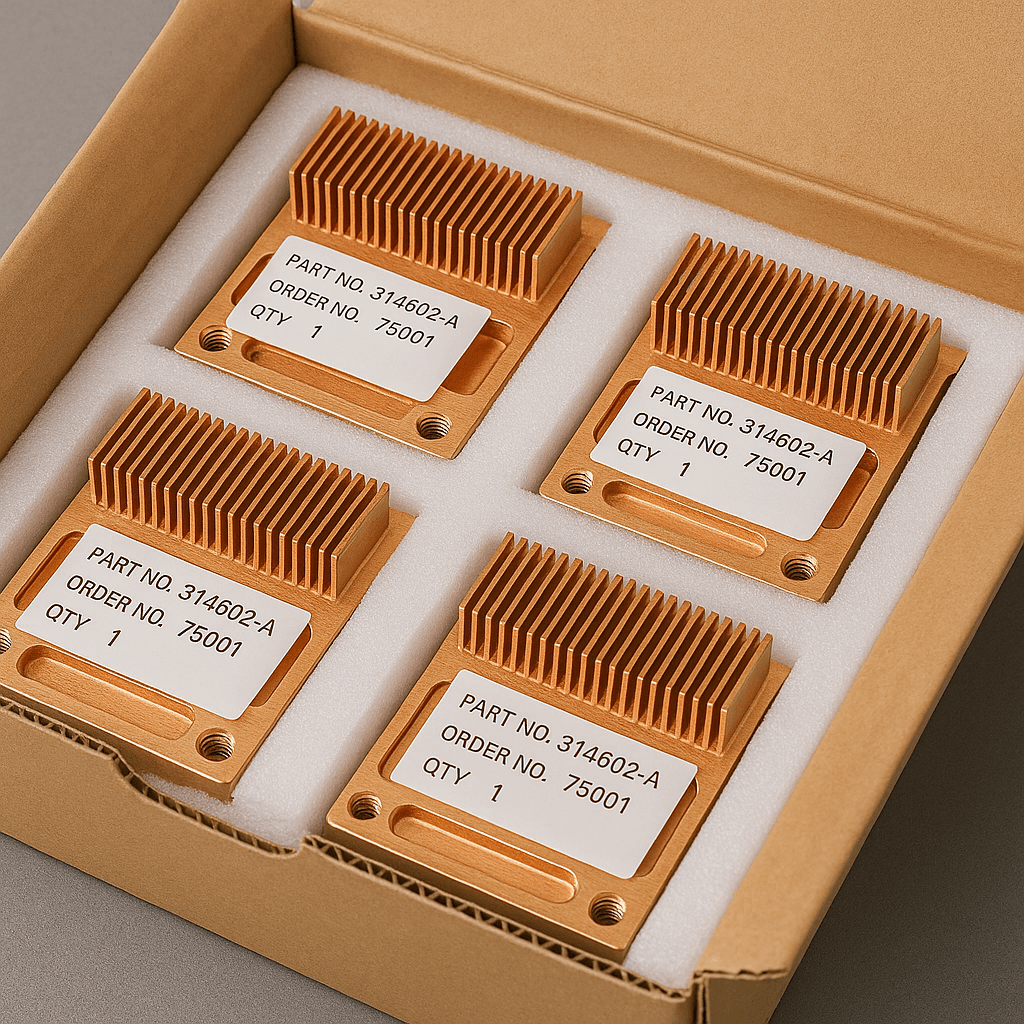

In Q4 2024, a UK-based electronics manufacturer specializing in industrial power modules and rail inverter systems reached out to us. They were developing a new high-power rectifier and urgently needed a custom copper heat sink machining solution that ensured tight tolerances, high thermal conductivity, and dimensional stability.

After facing persistent issues—deformation, poor surface finish, and assembly fit errors—from three previous vendors, the client found us via LinkedIn and our website. Our experience in thermal component prototyping, especially in oxygen-free copper machining, gave them the confidence to proceed with a trial order.

WhatsApp: +86 186-7086-9863

Email: freequote@alecmodel.com